Personal protective equipment in accordance with the ADR European international agreement on the transport of dangerous goods by r

The transport of hazardous materials in Serbia and in all other countries of the world requires strict regulations in order to avoid and minimize the safety risks of all transport participants and the environment. In order to minimize or reduce any accident - the concept of dangerous goods is defined by domestic laws, international agreements, and other regulations. ADR kit means the equipment that needs to be provided in case of dangerous goods transport, and this requirement comes from the European agreement on the international transport of dangerous goods by road (ADR). The contents of an ADR kit usually include first aid equipment, a fire extinguisher, warning signs and stickers, and personal protective equipment. The category of dangerous goods includes all substances that have toxic, corrosive or flammable properties and that can lead to explosions. According to ADR, dangerous goods represent a danger to people and the environment, and harmful substances are classified into several different categories: 1. Explosive substances 2. Flammable solids/Self-igniting substances/Substances that release flammable gas with water 3. Gas 4. Flammable liquids 5. Oxidizing substances/Organic peroxides 6. Toxic substances/Infectious substances 7. Radioactive substances 8. Corrosive substances 9. Various dangerous substances There are different types of ADR personal protective equipment kits, and choosing the right kit depends on the hazard class of the substance you are transporting. The vehicle must have the equipment prescribed by the Law on Road Traffic Safety and in accordance with the regulations in the ADR written instructions with the aim of ensuring the safety of the driver and the environment in case of any incident during the transport of goods. Driver protection equipment is mandatory during loading, unloading and in the event of an emergency. Any business that regularly transports hazardous materials requires at least one hazardous materials safety advisor who is responsible for ensuring that the company complies with hazardous materials regulations and obligations. The Albo company offers a complete range of personal protective equipment for the safe transport of harmful substances - chemical protection clothing, chemical and protective gloves, protective footwear, respiratory protection, safety glasses, workplace safety equipment, liquid absorbents and more. Clothing for protection against chemicals Chemical protective clothing belongs to the III category of personal protective equipment, which means that it is intended for hazards that can seriously and permanently damage health or lead to death. The appropriate chemical coverall can be selected in a few simple steps. To begin with, it is necessary to identify the aggregate state of the hazardous chemical - gaseous, liquid, vapor or solid particles. After that, safety personnel identify which of the six types of chemical coveralls are required as part of a risk assessment. Special attention should also be paid to the time period (length) of exposure to a certain chemical. Also, in order for the coverall to provide adequate protection, its size must be correctly selected.  Chemical gloves Contact with chemicals can be dangerous to workers' health and even life-threatening. That is why chemical gloves are a mandatory part of protection during contact with chemicals, along with all other protective equipment and prevention measures against spills and direct contact of the skin and other organs with chemicals. Chemical gloves can be made of different materials such as butyl rubber, neoprene, nitrile, latex and PVC. Orientation when choosing the appropriate type and model of chemical gloves is provided by the CAS table, which indicates the time (in minutes) of protection against the penetration of chemical substances (organic and inorganic solvents, as well as acids and bases) for a specific glove model.

Chemical gloves Contact with chemicals can be dangerous to workers' health and even life-threatening. That is why chemical gloves are a mandatory part of protection during contact with chemicals, along with all other protective equipment and prevention measures against spills and direct contact of the skin and other organs with chemicals. Chemical gloves can be made of different materials such as butyl rubber, neoprene, nitrile, latex and PVC. Orientation when choosing the appropriate type and model of chemical gloves is provided by the CAS table, which indicates the time (in minutes) of protection against the penetration of chemical substances (organic and inorganic solvents, as well as acids and bases) for a specific glove model.

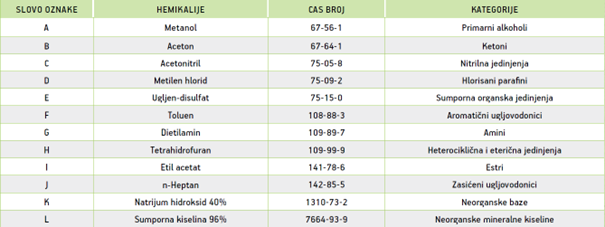

In order to correctly choose a glove for protection against chemicals, it is important to understand what the standard actually prescribes. The EN 374 standard includes test methods for 12 chemicals listed in the table below. Each chemical is designated by a different letter (from A to L) and to meet the standard manufacturers must test gloves for any 3 chemicals out of those 12.Every glove that meets the prescribed standard, i.e. shows resistance to 3 chemicals within 30 minutes, has three letters in addition to EN 374 (eg EN 374 JKL), which indicate the chemicals to which it is resistant. So, based on the basic description of the chemical glove, you can only know that the glove is resistant to the 3 listed substances.Some gloves are resistant to a large number of chemicals at the same time, and you can find that information in the technical sheet.

In order to correctly choose a glove for protection against chemicals, it is important to understand what the standard actually prescribes. The EN 374 standard includes test methods for 12 chemicals listed in the table below. Each chemical is designated by a different letter (from A to L) and to meet the standard manufacturers must test gloves for any 3 chemicals out of those 12.Every glove that meets the prescribed standard, i.e. shows resistance to 3 chemicals within 30 minutes, has three letters in addition to EN 374 (eg EN 374 JKL), which indicate the chemicals to which it is resistant. So, based on the basic description of the chemical glove, you can only know that the glove is resistant to the 3 listed substances.Some gloves are resistant to a large number of chemicals at the same time, and you can find that information in the technical sheet. Protective footwear Protective footwear is used when working in all branches of industry, as well as when working on tanks with dangerous substances, during contact with harmful substances and in places where there is a risk of spilling aggressive liquids. In addition to protection from physical and chemical hazards, modern protective shoes and boots also provide additional advantages of quality footwear - ergonomic design that ensures comfort, vapor permeability, anatomical insoles, antibacterial linings that reduce the possibility of unpleasant odors.

Protective footwear Protective footwear is used when working in all branches of industry, as well as when working on tanks with dangerous substances, during contact with harmful substances and in places where there is a risk of spilling aggressive liquids. In addition to protection from physical and chemical hazards, modern protective shoes and boots also provide additional advantages of quality footwear - ergonomic design that ensures comfort, vapor permeability, anatomical insoles, antibacterial linings that reduce the possibility of unpleasant odors.  Respiratory protection The risks to the respiratory organs are usually not visible to the naked eye, so they remain neglected, and the protection of the respiratory organs is not taken seriously enough. Pollution includes a chemical and physical change in the composition of the air that exceeds the possibility of human adaptation. Therefore, it is extremely important to apply adequate protection of the respiratory organs and choose the best means of protection, first of all in specific working conditions, but also in all other circumstances where any type of pollution has occurred. Protection of respiratory organs is of particular importance in order to avoid dangers that can lead to permanent damage to people's health.

Respiratory protection The risks to the respiratory organs are usually not visible to the naked eye, so they remain neglected, and the protection of the respiratory organs is not taken seriously enough. Pollution includes a chemical and physical change in the composition of the air that exceeds the possibility of human adaptation. Therefore, it is extremely important to apply adequate protection of the respiratory organs and choose the best means of protection, first of all in specific working conditions, but also in all other circumstances where any type of pollution has occurred. Protection of respiratory organs is of particular importance in order to avoid dangers that can lead to permanent damage to people's health.  Protective goggles Safety glasses belong to personal protective equipment for the face, the purpose of which is to protect the eyes and part of the face from splashing droplets, impacts of smaller and larger particles and various objects. They must be made of durable material, highly resistant to breaking, be light, comfortable and provide excellent visibility. The materials most commonly used to construct safety glasses include polycarbonate, acrylic, NKST polyurethane, and optical glass. Safety glasses are used in the entire industry, including the oil and gas industry.

Protective goggles Safety glasses belong to personal protective equipment for the face, the purpose of which is to protect the eyes and part of the face from splashing droplets, impacts of smaller and larger particles and various objects. They must be made of durable material, highly resistant to breaking, be light, comfortable and provide excellent visibility. The materials most commonly used to construct safety glasses include polycarbonate, acrylic, NKST polyurethane, and optical glass. Safety glasses are used in the entire industry, including the oil and gas industry.  Traffic signaling - Signal lamp to increase visibility that can be used independently or mounted on cones and barriers. - One-piece PVC cone in fluorescent orange color. It is intended for marking and signaling in traffic, road works and other outdoor works. - Absorbers for responding to accidental spills of oil, petroleum, oil derivatives and chemicals are specially designed equipment that absorb most spilled liquids. The range of liquid absorbent products helps to solve the problem of spills and pollution control, thus helping to preserve the environment. Spill safety equipment should be selected according to the nature and size of the accident or the need for its prevention. The equipment is divided into absorbents for oil, petroleum derivatives and universal absorbents. Absorbents are used in the petrochemical industry, at gas stations, when working on tanks with dangerous substances, in agriculture, when transporting dangerous substances, in marinas and in places where there is a risk of spilling aggressive liquids. Company Albo d.o.o. offers a complete range of personal protective equipment for the safe transport of harmful substances, and for all help and additional information when choosing equipment - the Albo team is at your disposal.[:]

Traffic signaling - Signal lamp to increase visibility that can be used independently or mounted on cones and barriers. - One-piece PVC cone in fluorescent orange color. It is intended for marking and signaling in traffic, road works and other outdoor works. - Absorbers for responding to accidental spills of oil, petroleum, oil derivatives and chemicals are specially designed equipment that absorb most spilled liquids. The range of liquid absorbent products helps to solve the problem of spills and pollution control, thus helping to preserve the environment. Spill safety equipment should be selected according to the nature and size of the accident or the need for its prevention. The equipment is divided into absorbents for oil, petroleum derivatives and universal absorbents. Absorbents are used in the petrochemical industry, at gas stations, when working on tanks with dangerous substances, in agriculture, when transporting dangerous substances, in marinas and in places where there is a risk of spilling aggressive liquids. Company Albo d.o.o. offers a complete range of personal protective equipment for the safe transport of harmful substances, and for all help and additional information when choosing equipment - the Albo team is at your disposal.[:]