Safe work at full speed with the JSP half mask FORCE 8™

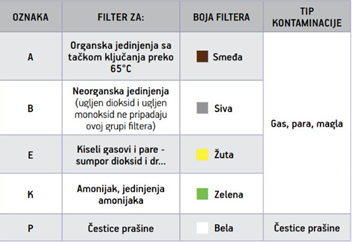

Protective masks and half masks are an indispensable part of the personal protective equipment of employees when the working environment belongs to one of the branches of heavy industry such as energy, mining, metallurgy or chemical industry. Using different types of filters, they protect against solid particles and pollution in the form of gases and steam. One of the biggest environmental pollutants is air pollution - whether it originates from artificial sources (industrial processes, heating plants, refineries) or from natural sources (bacteria, viruses, certain chemical reactions), it contains a chemical and physical change in the composition of the air that exceeds the possibility of human adaptation. As a result, it is extremely important to adequately protect the respiratory organs and choose the best means of protection in specific working conditions, but also in all other circumstances where air pollution occurs. Means for the protection of respiratory organs can be divided into means that filter the air in the environment and means with a separate air supply. RESPIRATORY PROTECTION MEANS THAT FILTER THE AIR Means that serve to protect the respiratory organs, and with which the air is filtered, are disposable masks, half-masks and full-face masks. When choosing the most adequate means to protect the respiratory organs, it is necessary to be careful with regard to the identification of contamination. Types of contamination: • Dust particles - they are created by the breaking or decomposition of solid materials. Adequate filters are chosen for half masks and full face masks, and the help and guide in the selection process is the classification of filters • Gas - a substance that is in a gaseous state at normal temperature, is characterized by the disordered movement of particles, and therefore the rapid expansion of the substance in space • Steam - follows the liquid aggregate state of the substance, it spreads in space more slowly than gases • Fog - is formed by condensation or atmospheric changes, which usually contain several chemical compounds Protection from solid particles (aerosols) The presence of small particles and aerosols in the work environment, usually almost invisible to the human eye, have an extremely bad effect on the health of employees, and can lead to the most serious illnesses. In such an environment, adequate protection can be provided by disposable masks, classified in the range from FFP1 to FFP3 respirator type. The type of disposable mask FFP (Face Filtering Piece) is categorized into three grades: • FFP1 – particle concentration does not exceed 4 x MDK • FFP2 – particle concentration does not exceed 10 x MDK • FFP3 – particle concentration does not exceed 30 x MDK MDK - maximum allowed concentration of particles in the working environment  Classification by efficiency and capacityProtection against harmful gases, steam and fog Adequate filters are selected for half masks and full face masks, and the classification of filters marked with the letters ABEKP, which is presented in the table, is a help and guide in the selection process.

Classification by efficiency and capacityProtection against harmful gases, steam and fog Adequate filters are selected for half masks and full face masks, and the classification of filters marked with the letters ABEKP, which is presented in the table, is a help and guide in the selection process.  Classification by type of contamination All types of protection can be combined with each other, thus resulting in combined filters such as, for example, ABEK2P3. EQUIPMENT WITH SEPARATE AIR SUPPLY In specific situations, atmospheric air filtration is not possible. Such atmospheric conditions are professionally called "Currently dangerous to health and life" (eng. IDHL). IDHL atmospheric environment is an environment that can lead an employee to the risk of death, disability, inability to self-rescue, injury or even the occurrence of acute diseases due to the following reasons: • when flammable gas, vapor or mist exceeds more than 10% of its lowest flammable limit (LFL) • when the concentration of combustible dust in the air is equal to or exceeds its lowest flammable limit (LFL) • when the atmospheric oxygen concentration is below 19.5% In situations where atmospheric air filtering is not possible, it is necessary to use devices with a separate air supply, independent of the atmospheric conditions that surround us.

Classification by type of contamination All types of protection can be combined with each other, thus resulting in combined filters such as, for example, ABEK2P3. EQUIPMENT WITH SEPARATE AIR SUPPLY In specific situations, atmospheric air filtration is not possible. Such atmospheric conditions are professionally called "Currently dangerous to health and life" (eng. IDHL). IDHL atmospheric environment is an environment that can lead an employee to the risk of death, disability, inability to self-rescue, injury or even the occurrence of acute diseases due to the following reasons: • when flammable gas, vapor or mist exceeds more than 10% of its lowest flammable limit (LFL) • when the concentration of combustible dust in the air is equal to or exceeds its lowest flammable limit (LFL) • when the atmospheric oxygen concentration is below 19.5% In situations where atmospheric air filtering is not possible, it is necessary to use devices with a separate air supply, independent of the atmospheric conditions that surround us.  JSP FORCE 8™ HALF MASK WITH REPLACEABLE FILTERS Using different types of filters, protective masks provide protection against solid particles and pollution in the form of gases and vapors. Respirators with valves and minimal inhalation resistance enable easier breathing, which contributes to worker safety and greater efficiency in performing work tasks. WHY USE FORCE 8™ HALF MASK? Half mask JSP Force 8 represents reliable certified protection of respiratory organs. Features a Typhoon™ exhaust valve for low breathing resistance and 4-point suspension with quick release clips. Thanks to the thermoplastic rubber from which it is made, it fits different face shapes. With the mask, filters are used to protect against particles, gases and vapors, depending on the type of protection that is necessary to provide in a certain working environment. It is certified in accordance with EN 140, EN 14387:2004 and EN 143:200 standards. Comfort during wear The Force 8 half mask is made of light, flexible and durable thermoplastic rubber that adheres well to the face and is comfortable to wear. One of the most important conditions for a proper fit and complete protection is that the user's face is shaved so that harmful gases do not enter through parts of the mask that do not fit the face due to the beard. Excellent sealing and fit to different face shapes is additionally achieved thanks to the 4-point fastening system with quick-release buckles. This way of adjusting and placing the mask allows the user to adjust it so that he is comfortable enough while wearing it, without compromising his safety and health. Typhoon exhaust valve Exhaust valves contribute to reducing breathing resistance and improving comfort, and can be of different performance levels. The JSP Typhoon™ valve is designed to ensure that air can easily escape through the valve and that there is minimal resistance when breathing. A high-performance valve like this reduces the user's breathing effort, i.e. contributes to comfort and convenience while wearing a half mask.

JSP FORCE 8™ HALF MASK WITH REPLACEABLE FILTERS Using different types of filters, protective masks provide protection against solid particles and pollution in the form of gases and vapors. Respirators with valves and minimal inhalation resistance enable easier breathing, which contributes to worker safety and greater efficiency in performing work tasks. WHY USE FORCE 8™ HALF MASK? Half mask JSP Force 8 represents reliable certified protection of respiratory organs. Features a Typhoon™ exhaust valve for low breathing resistance and 4-point suspension with quick release clips. Thanks to the thermoplastic rubber from which it is made, it fits different face shapes. With the mask, filters are used to protect against particles, gases and vapors, depending on the type of protection that is necessary to provide in a certain working environment. It is certified in accordance with EN 140, EN 14387:2004 and EN 143:200 standards. Comfort during wear The Force 8 half mask is made of light, flexible and durable thermoplastic rubber that adheres well to the face and is comfortable to wear. One of the most important conditions for a proper fit and complete protection is that the user's face is shaved so that harmful gases do not enter through parts of the mask that do not fit the face due to the beard. Excellent sealing and fit to different face shapes is additionally achieved thanks to the 4-point fastening system with quick-release buckles. This way of adjusting and placing the mask allows the user to adjust it so that he is comfortable enough while wearing it, without compromising his safety and health. Typhoon exhaust valve Exhaust valves contribute to reducing breathing resistance and improving comfort, and can be of different performance levels. The JSP Typhoon™ valve is designed to ensure that air can easily escape through the valve and that there is minimal resistance when breathing. A high-performance valve like this reduces the user's breathing effort, i.e. contributes to comfort and convenience while wearing a half mask.  Press-to-Check™ filters Force 8 half mask is used with filters with so-called "bayonet" hanging and replacement system, which minimally reduces the field of vision. The bayonet filter can be changed during operation without the risk of contaminated air entering the mask. If both bayonet filters are removed from the mask - it is not possible to breathe in the mask. A special innovation when it comes to bayonet filters that this mask uses are the filters. Thanks to their revolutionary design, they allow workers to quickly and reliably check for optimal sealing before entering the zone of increased risk. Press-to-Check™ filters are designed for minimal breathing resistance. The filter cartridge allows air to flow through the entire filter chamber to maximize performance. How to properly clean and maintain the half mask? JSP's high-quality and innovative respiratory protective equipment is developed and tested in a dedicated quality assurance laboratory, ensuring superior performance levels are achieved and maintained. Information on proper mask maintenance can be found in the accompanying user manual, and cleaning, maintenance and storage requirements may vary by product, so it is important to check the instructions for each respirator. The Force®8 JSP Mask is designed and manufactured to be fully user maintainable. It can be disassembled for cleaning, so users have a respirator they can reuse. The product may be stored in its original packaging or in additional PPE packaging to ensure that product contamination does not occur between uses.[:]

Press-to-Check™ filters Force 8 half mask is used with filters with so-called "bayonet" hanging and replacement system, which minimally reduces the field of vision. The bayonet filter can be changed during operation without the risk of contaminated air entering the mask. If both bayonet filters are removed from the mask - it is not possible to breathe in the mask. A special innovation when it comes to bayonet filters that this mask uses are the filters. Thanks to their revolutionary design, they allow workers to quickly and reliably check for optimal sealing before entering the zone of increased risk. Press-to-Check™ filters are designed for minimal breathing resistance. The filter cartridge allows air to flow through the entire filter chamber to maximize performance. How to properly clean and maintain the half mask? JSP's high-quality and innovative respiratory protective equipment is developed and tested in a dedicated quality assurance laboratory, ensuring superior performance levels are achieved and maintained. Information on proper mask maintenance can be found in the accompanying user manual, and cleaning, maintenance and storage requirements may vary by product, so it is important to check the instructions for each respirator. The Force®8 JSP Mask is designed and manufactured to be fully user maintainable. It can be disassembled for cleaning, so users have a respirator they can reuse. The product may be stored in its original packaging or in additional PPE packaging to ensure that product contamination does not occur between uses.[:]