What has the new EN ISO 20345: 2022 standard brought us?

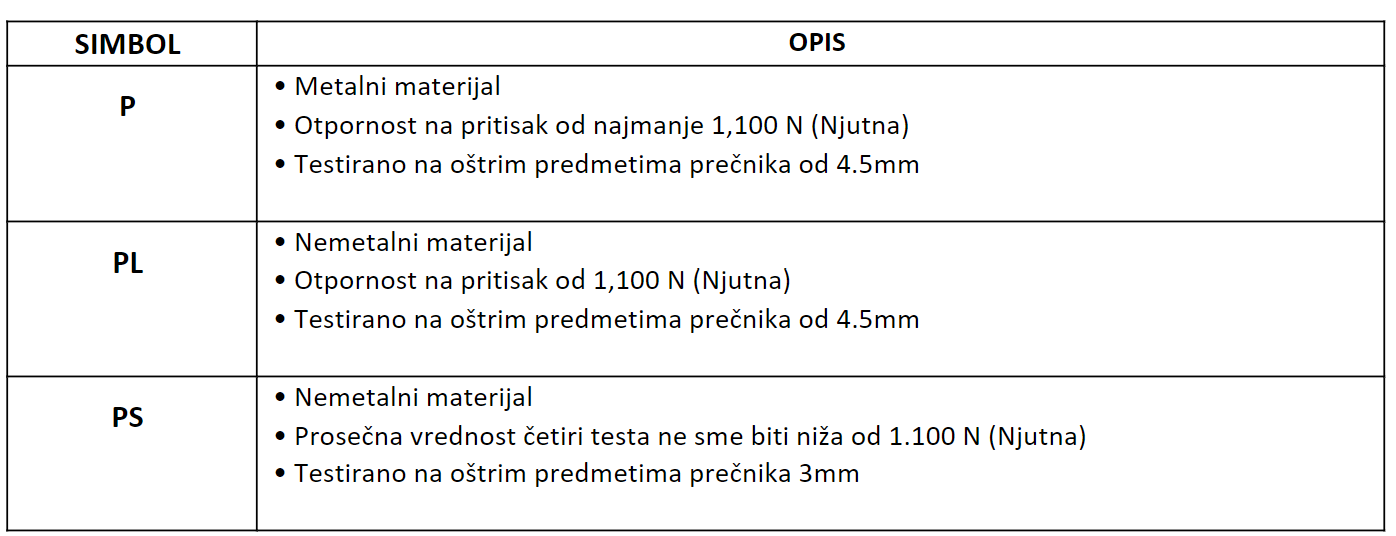

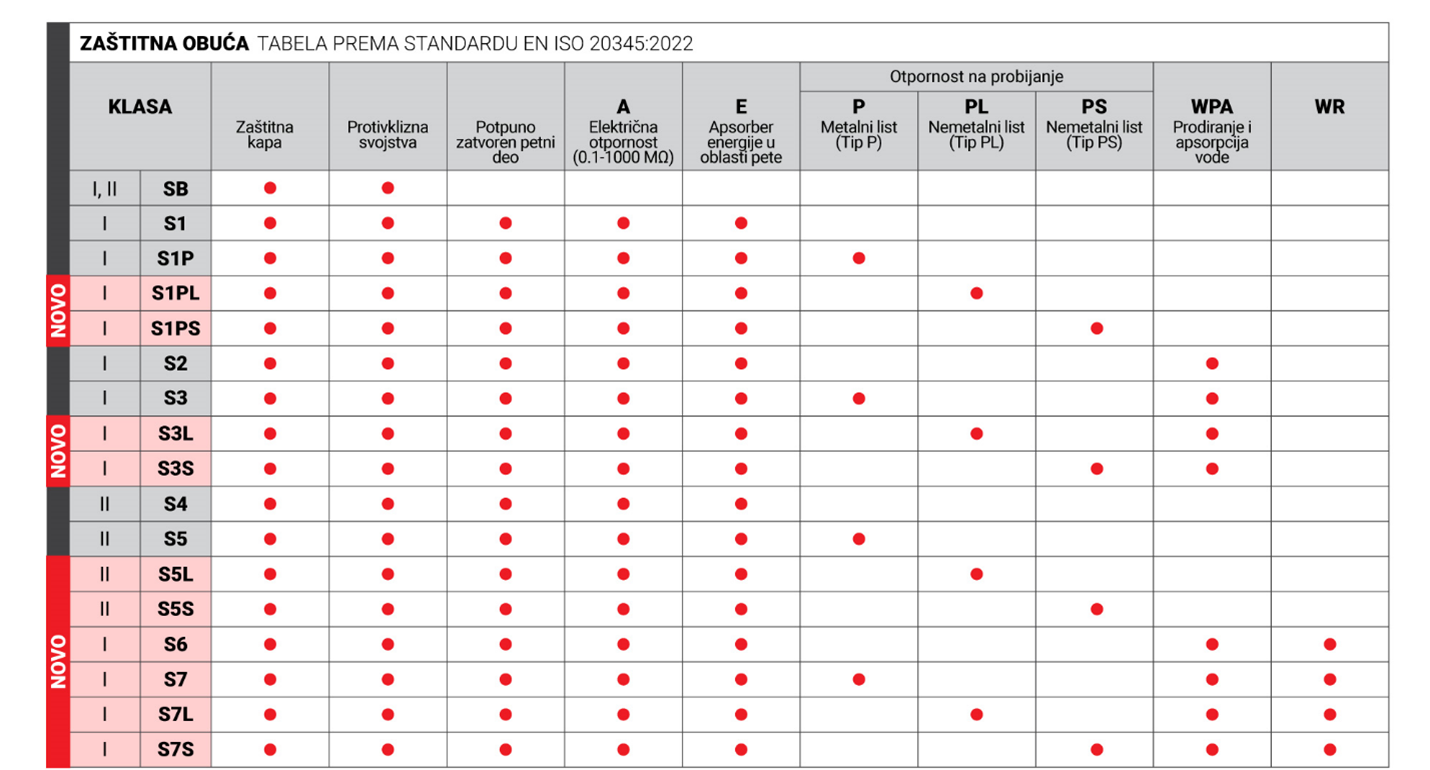

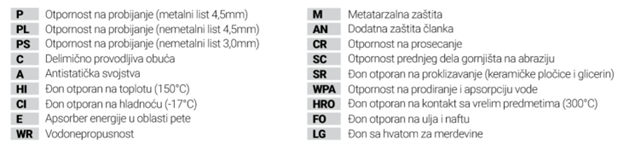

Last year brought us key changes in safety footwear certification – the existing standard EN ISO 20345:11 was updated and replaced with standard EN ISO 20345:2022. What is new and what has the new standard brought us? In the following text, we will present you with an overview of the most important changes: And the end for SRA, SRB, SRC - the beginning for SR The first and most important change concerns the skid resistance test procedure. The traditional SRA, SRB and SRC designations that were the industry standard will no longer be used. This does not mean that anti-slip testing will be abolished, but that more rigorous testing methods will be used to make a shoe slip resistant (SR) certified. SR test methods have been adapted to better mimic real-world usage conditions. All anti-slip tests are now performed on ceramic tiles with glycerin, ensuring that the test results more accurately approximate the real situations in which the footwear will be used. This provides additional assurance and security for both manufacturers and end users. II New symbols P, PL and PS and their meaning Recent changes in the standardization of safety footwear have also brought important innovations in terms of marking the type of sheet used. The term "penetration resistance" has been replaced by the term "penetration resistance". This change is in line with the new ISO standards 22568-3 and 22568-4 which replace the older EN 12568 standard. Also, new symbols have been introduced to indicate the certification of safety footwear in terms of puncture resistance. The new standard specifies in more detail the materials used for the production of the safety data sheet. The designation P now indicates a sheet made of metallic materials (eg aluminium), while PL and PS indicate a protective sheet made of non-metals (eg Kevlar).  III New levels of protection The earlier classification system was divided into SB, S1, S2, S3, S4 and S5 where SB was the only level of protection that allowed an open heel. The S1 protection level also had additional puncture protection called S1P, while the S4 and S5 levels were intended for boot classification. The new system includes levels SB, S1, S2, S3, S4, S5, S6 and S7. Protection level S1 with puncture protection will continue to be marked with the suffix P, i.e. S1P. However, since the puncture protection tests have been extended to P, PL and PS, level S1 can be specified with these additions; S1P, S1PL and S1PS. For other protection levels from S3 to S7 that already include puncture protection, they are not extended to P, PL and PS, because the protection level itself already indicates that the product meets these requirements. As we can see, two new levels of protection have also been introduced: S6 and S7, which focus on waterproofing. S6 - This level of protection corresponds to the protection requirements of S2, but with additional requirements for water resistance (WR - Water Resistant). S7- Similarly, S7 corresponds to the protection requirements of S3, also with additional requirements for waterproofing. It is important to note that the WR designation will no longer be visible in the protection listing as it used to be (eg S2 WR designation - now S6)

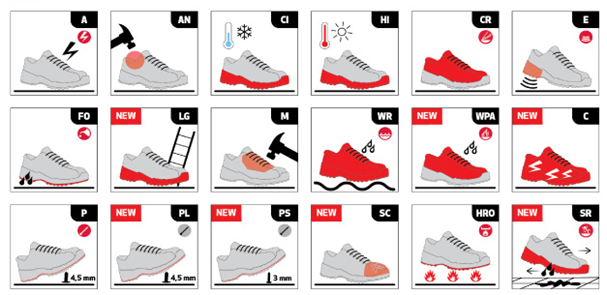

III New levels of protection The earlier classification system was divided into SB, S1, S2, S3, S4 and S5 where SB was the only level of protection that allowed an open heel. The S1 protection level also had additional puncture protection called S1P, while the S4 and S5 levels were intended for boot classification. The new system includes levels SB, S1, S2, S3, S4, S5, S6 and S7. Protection level S1 with puncture protection will continue to be marked with the suffix P, i.e. S1P. However, since the puncture protection tests have been extended to P, PL and PS, level S1 can be specified with these additions; S1P, S1PL and S1PS. For other protection levels from S3 to S7 that already include puncture protection, they are not extended to P, PL and PS, because the protection level itself already indicates that the product meets these requirements. As we can see, two new levels of protection have also been introduced: S6 and S7, which focus on waterproofing. S6 - This level of protection corresponds to the protection requirements of S2, but with additional requirements for water resistance (WR - Water Resistant). S7- Similarly, S7 corresponds to the protection requirements of S3, also with additional requirements for waterproofing. It is important to note that the WR designation will no longer be visible in the protection listing as it used to be (eg S2 WR designation - now S6)  IV Expansion of Additional Requirements for Protective Footwear New changes in safety footwear standards include an increase in the number of additional requirements from 12 to 18. Some of the previous requirements have been removed and become part of the basic certification, while others have been newly introduced. Here are some key new additional requirements: 1. Front wear resistance - Scuff Cap (SC) The Scuff Cap or protection from scratches on the shoe flap now requires a Martindale abrasion test of 8,000 cycles. According to this test, the overlay on the footwear must not develop holes through its entire thickness. 2. Slip Resistance (SR) As we have already mentioned, the new additional requirement for checking the slip resistance of safety shoes is tested on ceramic tiles with glycerin. The permissible coefficient of friction is >= 0.19 mm when the heel slides forward and >= 0.22 mm when the front part of the shoe slides backward. 3. Sole with ladder grip - Ladder Grip (LG) For a better grip on the ladder, the sole of the protective footwear must have a transverse profile with a height of at least 1.5 mm in the ankle area. This test is designed to evaluate how the footwear provides stability and safety when climbing a ladder. It is important to note that this test is one of several optional additional tests. However, it provides added value and safety in choosing footwear, especially for professionals who often use ladders in their work. 4. Oil and oil resistance (FO) The FO mark, which indicates the sole's resistance to oils and petroleum, was a mandatory part of the standard for protection levels S1 to S5. This means that all closed-heel safety shoes had to meet this standard. However, in the new standardization system, FO becomes an additional test and not a mandatory part of the standard. This means that testing for resistance to hydrocarbons will be optional, only carried out for those footwear models intended for use in environments where hydrocarbons are present. This change allows greater flexibility and specialization of safety footwear, allowing manufacturers to adapt their products to the specific requirements of work environments. 5. Resistance to water penetration and absorption (WRU/WPA) According to the "old" standard, footwear marked with S2 or S3 had an upper part that is water-repellent (WRU - Water Repellent Upper). However, only the material itself was tested, not the shoe as a whole, which meant that the footwear could lose its water resistance at joints and seams. In the new standard, the WRU designation disappears and is replaced by a new WPA designation that refers to resistance to penetration and absorption of water (refers to testing the penetration and absorption of water into the material).

IV Expansion of Additional Requirements for Protective Footwear New changes in safety footwear standards include an increase in the number of additional requirements from 12 to 18. Some of the previous requirements have been removed and become part of the basic certification, while others have been newly introduced. Here are some key new additional requirements: 1. Front wear resistance - Scuff Cap (SC) The Scuff Cap or protection from scratches on the shoe flap now requires a Martindale abrasion test of 8,000 cycles. According to this test, the overlay on the footwear must not develop holes through its entire thickness. 2. Slip Resistance (SR) As we have already mentioned, the new additional requirement for checking the slip resistance of safety shoes is tested on ceramic tiles with glycerin. The permissible coefficient of friction is >= 0.19 mm when the heel slides forward and >= 0.22 mm when the front part of the shoe slides backward. 3. Sole with ladder grip - Ladder Grip (LG) For a better grip on the ladder, the sole of the protective footwear must have a transverse profile with a height of at least 1.5 mm in the ankle area. This test is designed to evaluate how the footwear provides stability and safety when climbing a ladder. It is important to note that this test is one of several optional additional tests. However, it provides added value and safety in choosing footwear, especially for professionals who often use ladders in their work. 4. Oil and oil resistance (FO) The FO mark, which indicates the sole's resistance to oils and petroleum, was a mandatory part of the standard for protection levels S1 to S5. This means that all closed-heel safety shoes had to meet this standard. However, in the new standardization system, FO becomes an additional test and not a mandatory part of the standard. This means that testing for resistance to hydrocarbons will be optional, only carried out for those footwear models intended for use in environments where hydrocarbons are present. This change allows greater flexibility and specialization of safety footwear, allowing manufacturers to adapt their products to the specific requirements of work environments. 5. Resistance to water penetration and absorption (WRU/WPA) According to the "old" standard, footwear marked with S2 or S3 had an upper part that is water-repellent (WRU - Water Repellent Upper). However, only the material itself was tested, not the shoe as a whole, which meant that the footwear could lose its water resistance at joints and seams. In the new standard, the WRU designation disappears and is replaced by a new WPA designation that refers to resistance to penetration and absorption of water (refers to testing the penetration and absorption of water into the material).

Transition Period for Safety Footwear Certification according to EN ISO 20345: 2022 Safety footwear that was placed on the market after March 30, 2023 must be certified in accordance with the new standard EN ISO 20345: 2022. However, for safety footwear that is already on the market and whose certificate is still valid, it is not necessary to perform certification according to to the new standard until the certificate expires, even if it is after March 30, 2023. The EU type examination (certificate) is valid for 5 years. This means that in the coming period there will be products certified according to both new and old standards on the market. If you are looking for protective shoes, Albo offers a wide range of models that will suit your needs. Explore the offer on the albo.biz site and find the ideal pair that will provide both comfort and protection at work. The Albo company has been taking care of user safety at work for 32 years with an assortment that has a wide selection of work and protective footwear, and our colleagues are always available for all consultations and additional information.[:]

Transition Period for Safety Footwear Certification according to EN ISO 20345: 2022 Safety footwear that was placed on the market after March 30, 2023 must be certified in accordance with the new standard EN ISO 20345: 2022. However, for safety footwear that is already on the market and whose certificate is still valid, it is not necessary to perform certification according to to the new standard until the certificate expires, even if it is after March 30, 2023. The EU type examination (certificate) is valid for 5 years. This means that in the coming period there will be products certified according to both new and old standards on the market. If you are looking for protective shoes, Albo offers a wide range of models that will suit your needs. Explore the offer on the albo.biz site and find the ideal pair that will provide both comfort and protection at work. The Albo company has been taking care of user safety at work for 32 years with an assortment that has a wide selection of work and protective footwear, and our colleagues are always available for all consultations and additional information.[:]