Industrial processes release substances that are very harmful to human health. Diseases caused by inhalation of toxic substances occur gradually, their causative agents are mostly invisible to the naked eye, and the consequences are permanent and often fatal. That is why it is important to choose adequate means of protection of the respiratory organs, in the industry these are most often masks of the FFP level of protection – industrial respirators.

Means for the protection of respiratory organs, as well as personal protective equipment as a whole, must not be the first or only solution for controlling the exposure of workers to harmful substances. They represent the supplement and final solution of all safety measures taken by occupational safety engineers in order to eliminate the need for workers to stay in the danger zone. All risks to the health and safety of workers, including respiratory risks, along with ways to protect against their impact, are described in the umbrella safety document – the Risk Assessment Act.

Risks to human health

Occupational respiratory diseases are caused by frequent or long-term exposure to harmful substances in the air. Sometimes even a single exposure to extremely toxic fumes is enough to cause lung damage or poisoning.

According to some studies, mortality from lung diseases accounts for 70% of the total mortality from occupational diseases. The most common occupational respiratory diseases are asthma, chronic obstructive pulmonary disease, lung cancer, pneumoconiosis, silicosis, asbestosis, allergic bronchioalveolitis.

Harmful substances released in industrial processes can be in different forms, such as gas, steam, fog, smoke, dust. All of them in the air give off a mixture of particles called aerosols.

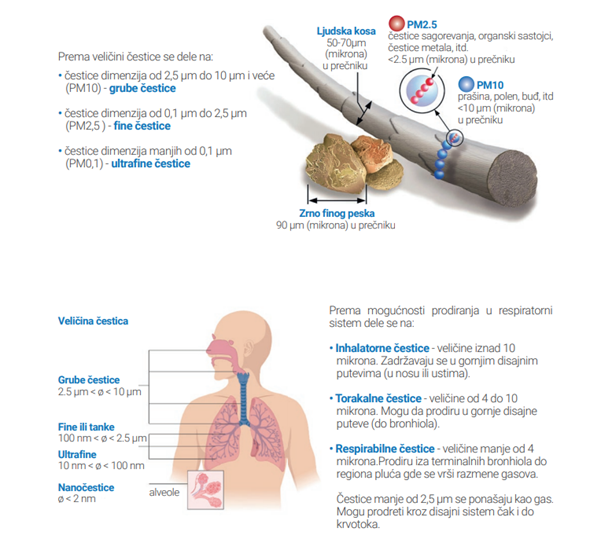

Aerosol particles can vary in size from a few nm to several tens of μm in diameter. The size of the particles is one of the most important parameters affecting their effect on human health and the possibility of deposition in the respiratory system.

Surgical or FFP masks?

Surgical masks are primarily intended to protect the environment from the wearer. When it comes to particulate air pollution in industrial conditions, surgical masks do not provide the necessary protection because the material from which they are produced cannot filter the polluted air. This is supported by the fact that surgical masks belong to category I personal protective equipment, while FFP masks belong to category III personal protective equipment. In addition, the edges of surgical masks do not create a complete seal, which would prevent the ingress of particles. Therefore, if there is no tight fit of the respirator on the wearer’s face, the contaminated air will pass through every gap, that is, through every space that did not rest on the face. The conclusion is clear – for protection against particles released in industrial processes, the basic level of respiratory protection is represented by FFP masks.

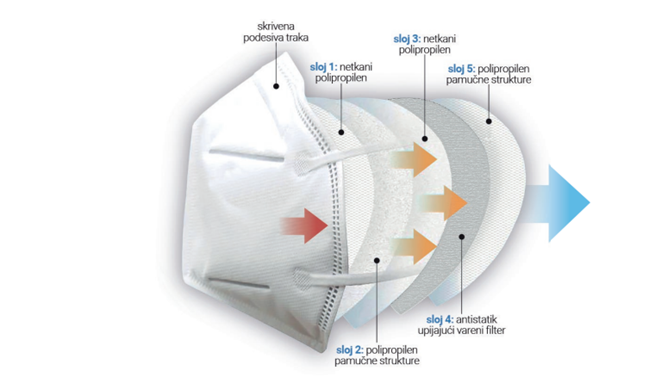

Respirators can consist of 3 to 5 layers of filtration material. The cross-section shows what an industrial respirator consists of.

Types of respirators

The basic division of disposable respirators is according to the level of protection, that is, the level of filtration of particles from the air. MDK – the maximum allowed amount of harmful substances in the working environment are the concentrations and doses to which, according to current knowledge, workers at the workplace can be exposed 8 hours a day, 5 days a week, during their working life, without their health being endangered. The numerical value of MDK is usually two to three times lower than the concentration and dose that causes chronic disease.

Types of mask FFP (eng. Face Filtering Piece):

FFP1 – Particle concentration does not exceed 4xMDK

These masks filter low levels of fine non-toxic and non-fibrogenic dust, oil or water-based fumes typical of manual sanding, drilling and cutting. FFP1 masks filter at least 80% of particles up to 0.6 µm in size, while total leakage can be a maximum of 25%. FFP1 masks are often used in the construction or food industry, where toxic or fibrogenic types of dust and aerosols are not expected.

FFP2 – Particle concentration does not exceed 10xMDK

These masks filter intermediate levels of fine dust and oil or water-based fumes typical of plastering, cement application, sanding and woodworking dust. FFP2 masks protect against smoke, aerosols and harmful particles that can be fibrogenic, which means that they irritate the respiratory system in a short period and can lead to a decrease in the elasticity of the lung tissue in the long term. FFP2 masks filter at least 94% of particles up to 0.6 µm, while total leakage can be at most 11%. They are often used in the metal processing industry and mining where workers are exposed to smoke, smog, and harmful aerosols.

FFP3 – Particle concentration does not exceed 30xMDK

These masks filter high levels of fine dust and oil or water-based vapors typical of hazardous dust handling in the pharmaceutical industry or when working with biological agents and fibers. FFP3 masks provide maximum protection against air pollution. They protect against toxic and harmful types of dust, smoke and aerosols. They also protect against carcinogenic substances, radioactive substances and pathogens such as viruses, bacteria and fungal spores. They filter at least 99% of particles with a size of 0.6 µm, while the total leakage can be a maximum of 5%. FFP3 masks are often used in the chemical industry.

In addition to the level of protection, respirators also differ in some other properties they may have.

According to the shape, respirators can be:

• Round (spherical)

• Horizontally foldable

• Vertically foldable

The shape of the disposable protective mask does not affect the degree of protection, but only the comfort of the user, preferring one of the shapes is a completely individual matter.

Respirators with activated carbon have the ability to neutralize unpleasant odors and are used in welding processes, waste disposal, work with organic vapors, and wherever, in addition to air pollution, there is also the presence of unpleasant odors.

Respirators can be with or without an exhaust valve, which has the property of reducing the accumulation of moisture and heat inside the mask, which makes work easier, especially in warm and humid environments. The exhaust valve reduces breathing resistance, makes breathing easier and thus facilitates long-term and physically strenuous work. The valve does not affect the degree of protection, only comfort.

According to the length of the period of use, respirators can be disposable or reusable. Disposable respirators that are intended for use during one work shift by one person are labeled “NR” (non reusable). When there is a high concentration of particles in the air, it may be necessary to use several masks during one shift, because the filtration material quickly becomes saturated with particles and makes it difficult for the user to breathe.

Reusable respirators marked “R” (reusable) can be reused or used in another shift after cleaning with specially designed means.

N95 respirators – The road from fashion to heavy industry

The American N95 standard is identical to the European protection level FFP2 and has an interesting history.

The first disposable N95 respirators were developed by the 3M company and approved in 1972, based on research into the use of melt-blown polypropylene by designer Sarah Turnbull during the sixties of the 20th century. The material was previously used to make decorative ribbons, bows, straps, bras and the company developed the technology and applied it to the corresponding filter.

Under the microscope they look like someone dropped a bunch of sticks and there are huge gaps between them. When the particles fly into the wand maze, they get stuck as they spin. In addition to these physical barriers with which the mask filters particles, what gives it its effectiveness is the invisible electrical charge inside the mask.

“We realized that if we can put a charge in the fibers, then in addition to the mechanical force, there is also a static force,” said scientist Dr. Peter Tsai.